Although the die-casting process was developed in the 19th century, only lead alloys and different lead compositions were used. However, Aluminum has revolutionized the entire concept of this remarkable process.

Aluminum Is Ideal For Die Casting:

The growing popularity of Aluminum in the die-cast Aluminum industry is due to its mild and anti-corrosive nature. Apart from this, these metals have high dimensional stability for complex shapes and thin walls. High thermal and electrical conductivity, as well as the ability to withstand high temperatures, make aluminum die casting a very popular choice today.

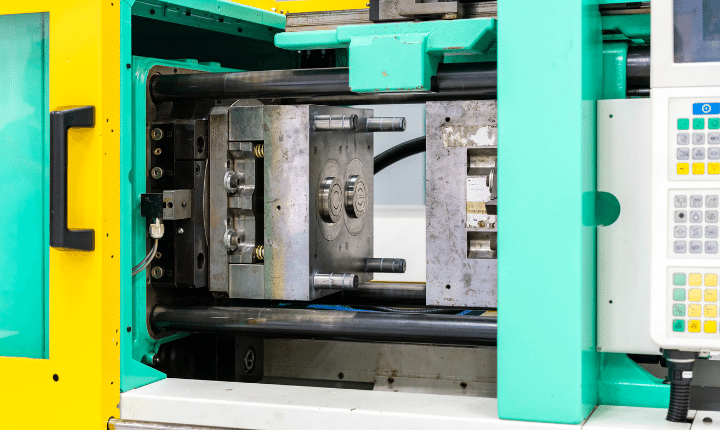

Cold Room And Cast Aluminum Machine:

Typically, cold chamber machines are used to melt aluminum, Aluminum has a high melting point. This process involves pouring the molten metal into a “cold chamber” or a cylinder arm. This can be done manually with a manual spoon or with an automatic spoon. The next step is to close the hole in the cold chamber and force the metal into the die to be locked at a high pressure using a hydraulically operated plunger.

Automatic Die Casting Machine:

The die-cast Aluminum has been significantly improved and manual operation has succeeded in replacing automatic quality control. Nowadays, different types of machines are used in the die casting process, which can make your work easier, save time and increase your productivity. While some buttons use different tools to lubricate the prints, the metal spoon in the cold room machine uses it to integrate other functions such as cooling and casting processes.

Even to adjust the casting machine and secure the stable castings, there is a current microprocessor. You can get the metal speed, drawbar position, hydraulic pressure and other data with this machine. Finally, all this contributes to the statistical analysis of good quality control.

Suitable Design For High Quality Die Casting:

In addition to the use of automatic machines, to obtain the appropriate Aluminum casting products, there needs to be a large design team to collaborate with casting experts. It is an important prerogative at the beginning of the design to obtain a quality end product. It also reduces unnecessary costs during the tool-making phase and cast aluminum production. Proper design and planning always lead to the correct implementation, providing quality products and longer lifespan. This also applies to zinc smelting. It is the prerogative to get the best aluminum casting products at the moment.

Commented Posts